A Comprehensive Guide to Different Kinds of Galvo Scanners and Their Applications

Galvo scanners, known for their speed and precision, are essential to a variety of markets from manufacturing to clinical modern technology. The journey to selecting the optimal galvo scanner for your functional demands begins with understanding these subtleties.

Basic Summary of Galvo Scanners

Galvo scanners, short for galvanometer scanners, are precision devices made use of to route laser light beams accurately and swiftly across a designated area. Fundamentally, a galvo scanner is composed of a tiny, lightweight mirror affixed to a galvanometer, which is an electromechanical device that gauges electrical existing by deflection of a needle.

The core principle behind galvo scanners is the specific and fast control of the mirror's angle, which consequently changes the instructions of the laser light beam. This is achieved with a closed-loop feedback system that makes certain the mirror's placement is constantly monitored and adjusted for accuracy. The responses system consists of placement sensing units, control electronic devices, and high-performance motors, delivering outstanding responsiveness and precision.

Galvo scanners succeed in applications calling for elaborate and recurring laser motions, such as laser engraving, reducing, and clinical imaging. Their ability to run at broadband without compromising precision makes them indispensable in situations demanding both efficiency and accuracy.

Kinds of Galvo Scanners

When discovering the types of galvo scanners, it's essential to recognize that variations are mainly based on their layout, application needs, and performance requirements. Generally, galvo scanners can be classified into single-axis and dual-axis versions.

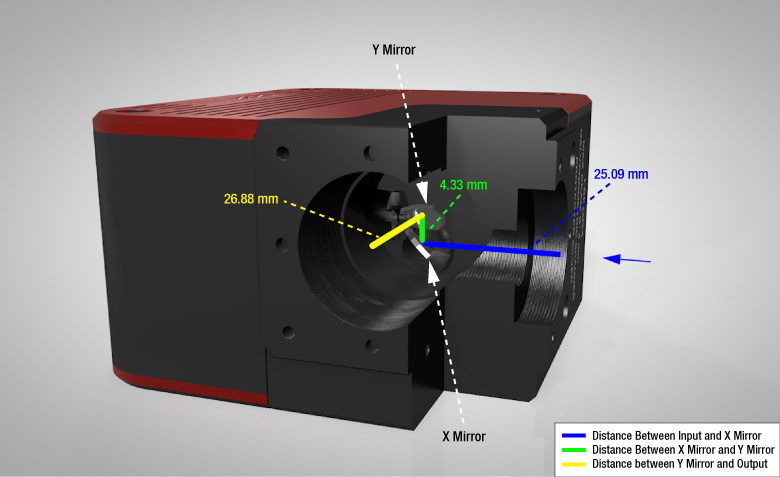

Dual-axis galvo scanners, on the other hand, supply two-dimensional control of the light path. This makes them crucial in even more complicated applications like laser light shows, 3D printing, and medical imaging. Dual-axis versions are usually equipped with 2 mirrors and matching galvanometers, enabling vibrant control over both X and Y works with.

Trick Features to Think About

Numerous crucial features must be meticulously examined when picking a galvo scanner for your particular application. Speed is a critical quality, as it establishes the scanner's ability to manage high-frequency jobs successfully. The speed is typically determined in regards to response time and the maximum variety of factors per 2nd the scanner can deal with.

One more essential function is the scanner's range of movement, which shows the maximum angular deviation it can attain. A broader variety provides higher adaptability but may call for much more innovative control systems. Thermal stability also requires attention, as temperature level variations can affect efficiency; thus, go with scanners with robust thermal administration systems.

Industry-Specific Applications

In numerous sectors, galvo scanners play a pivotal duty by improving accuracy and effectiveness in specialized applications. In the clinical field, galvo scanners are important to laser surgeries and ocular treatments, where high-speed, precise beam of light positioning is important. These tools enable minimally invasive surgeries by specifically targeting cells, hence decreasing recovery times and enhancing client results.

In manufacturing, galvo scanners are vital for laser inscription, reducing, and welding. Their ability to promptly and accurately direct laser beam of lights makes sure high-grade coatings and detailed describing, which is crucial for the production of complex parts in automobile, aerospace, and electronic devices markets. The textile industry also profits from galvo scanners in textile cutting and inscription, providing both rate and precision in handling varied materials.

Choosing the Right Galvo Scanner

Choosing the appropriate galvo scanner is an important decision that hinges on numerous key variables, consisting of application requirements, efficiency specifications, and budget constraints. Clearly define the application demands. Whether the scanner is planned for laser inscription, clinical imaging, or 3D printing, each application requires certain performance attributes such as resolution, accuracy, and speed.

2nd, think about the performance specifications. Criteria like scan angle, action time, and thermal security are important (galvo scanner). A high-speed galvo scanner with a broad scan angle is perfect for large-area marking, while applications requiring fine detail may focus on high resolution and accuracy

Third, represent budget plan constraints. High-performance galvo scanners include a substantial financial investment, however their lasting advantages can exceed preliminary costs. Evaluate the overall expense of ownership, including maintenance, to guarantee the selected scanner gives value over its life-span.

Final Thought

Comprehending the diverse kinds of galvo scanners and their unique capacities is essential for maximizing performance across various sectors. Single-axis and dual-axis models satisfy different operational complexities, while high-speed and high-precision variations resolve specific demands in manufacturing, textiles, medical fields, and 3D printing. Careful selection based upon the distinct features and application demands of each type of galvo scanner guarantees enhanced performance and accuracy, thus dramatically improving overall functional outcomes.

Galvo scanners, brief for galvanometer scanners, are accuracy tools used to guide laser beam of lights accurately and rapidly across an assigned area.When discovering the types of galvo scanners, it's essential to recognize that variations are largely based on their design, application requirements, and performance specs. Each type of galvo scanner is hence distinctly tailored to meet details operational requirements, making sure optimum efficiency throughout various applications.

The precision of a galvo scanner straight impacts the quality of the result, making it crucial to think about the scanner's read what he said capability to preserve high-resolution performance (galvo scanner). Careful selection based on the one-of-a-kind attributes and application needs of each kind of galvo scanner makes sure improved performance and precision, consequently considerably enhancing general functional results